CAB BRAZED

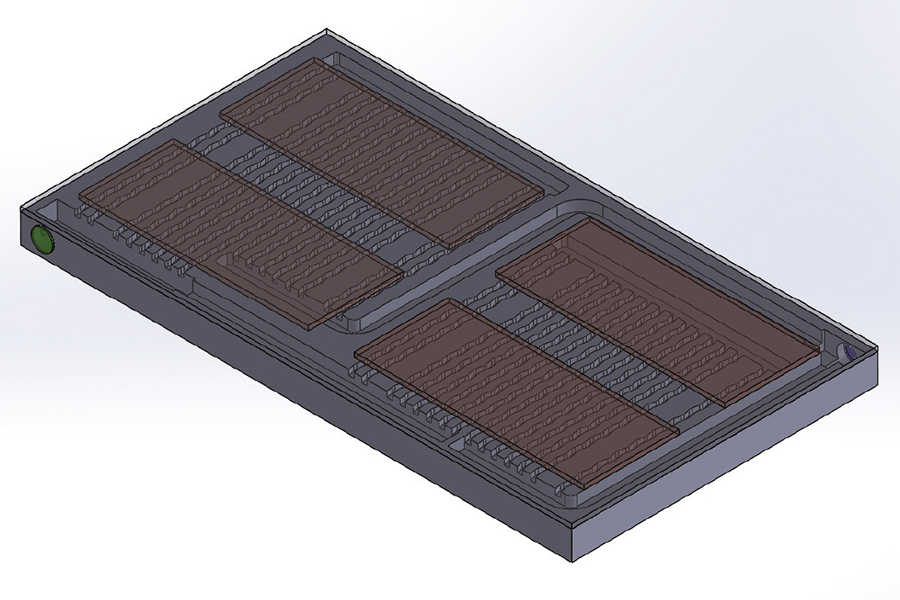

Using Controlled Atmosphere Brazing, Mecc.Al can achieve the most efficient heat dissipation for the more extreme projects and design. This product range uses different aluminum alloys and is designed and manufactured entirely within the engineering division of the company, customizing the fine detail of every single part produced with the use of the most sophisticated and up-to-date Computational Fluid Dynamics (CFD) design software.

Where it is appropriate to the client's project, brazing in controlled atmosphere is a sophisticated manufacturing technology specifically applied to thermal management systems that allows us to customize the design and the cooling features of the plate to its maximum limits, using special aluminum alloys.

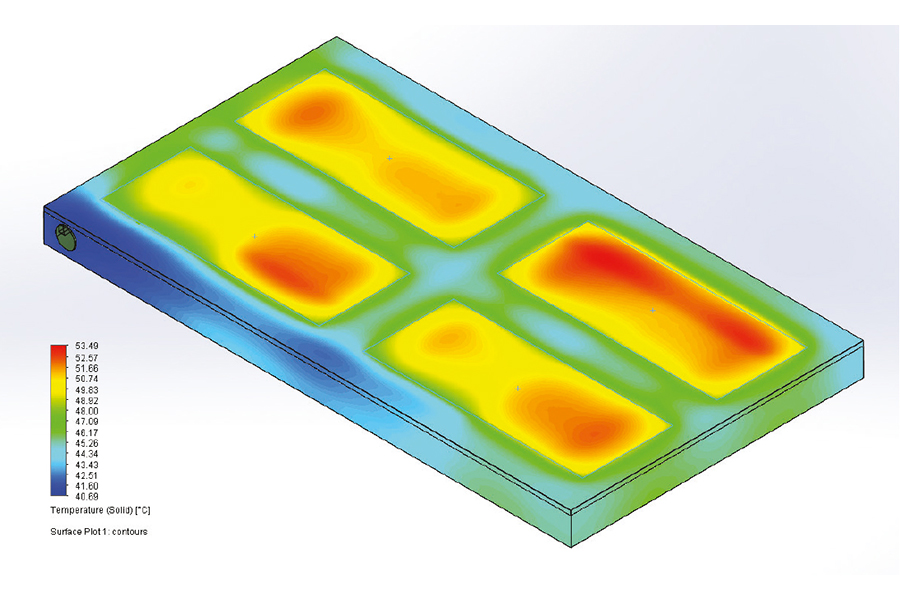

The projects requiring the highest thermal performance use this technology to ensure complete cooling uniformity under the overall area used by semiconductors and the active components.

Developed by the Engineering Department of Mecc.Al, internal channel designs (with or without the use of turbulators) are defined through the use of sophisticated 3D design programs and CFD (Computational Fluid Dynamics) simulation. This optimises the design for internal flows and the required pressure drop, allowing the construction of LCPs without any constraint on internal and external shape. CAB Plates may be completed with connectors of any type, diameter and thread pitch both integrated and external to the plate.