FRICTION STIR WELDING

By introducing the latest and cost effective FSW welding technology in the production of the liquid cooled plates, Mecc.Al meets the needs of power dissipation in projects that require high performance levels and competitiveness.

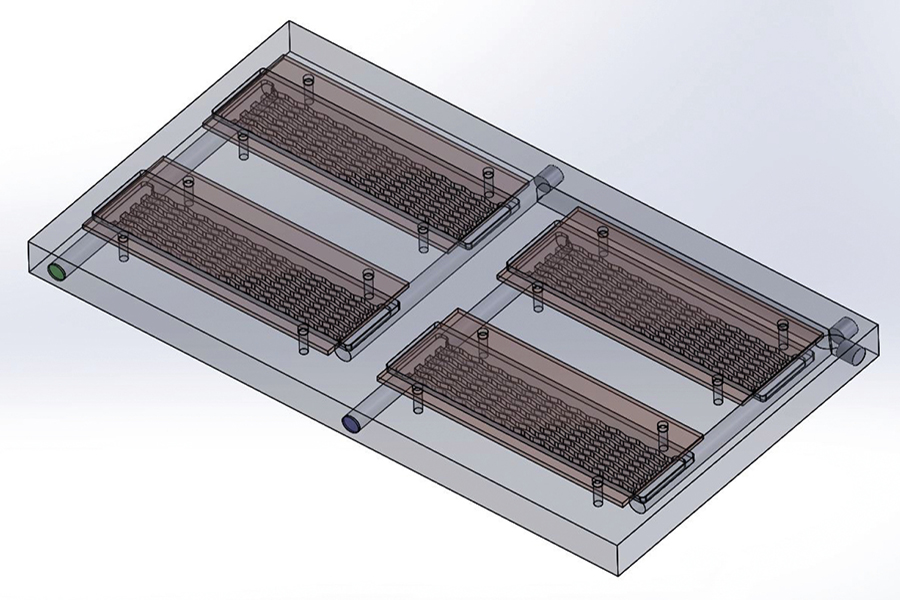

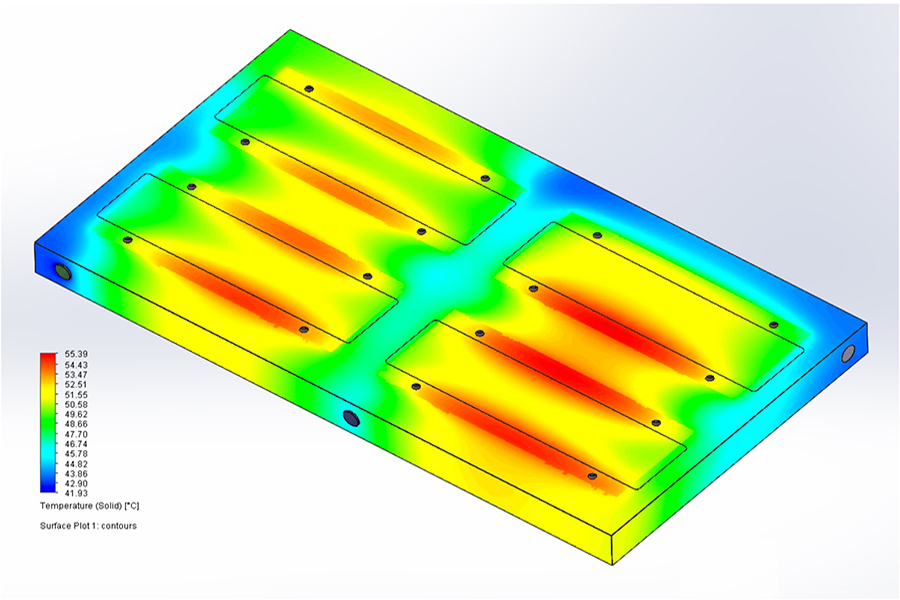

A FSW liquid cooled plate can be made of several materials and aluminum alloys, besides the internal cooling channel layout is customized and designed by Mecc.Al technical department team using CFD software and according to each project specification.

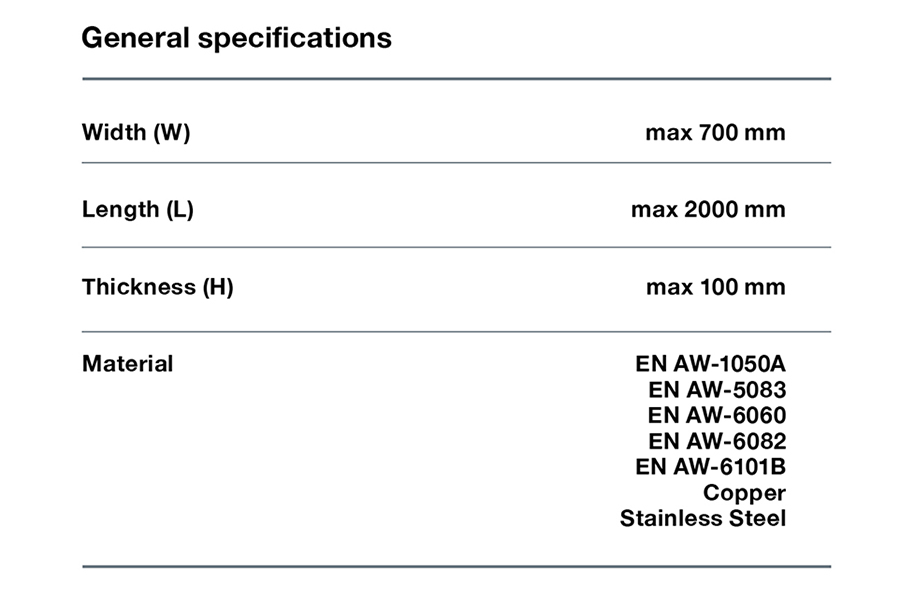

Friction Stir Welding is a solid-state joining method that applying to a construction of a liquid cooled plate allows to achieve very strong hermetic seal and high thermal performance, offering one of the most cost effective solution in cooling technologies. Depending on the system specification, several materials and aluminium alloys can be used for the realization of a FSW LCP. Dimensions and shape of the internal cooling channels are designed by Mecc.Al thermal engineers through advanced 3D and computational fluid dynamics simulation software, allowing the optimization of both the pressure drop and the liquid flow to consequently reach a very high efficiency level.