The production

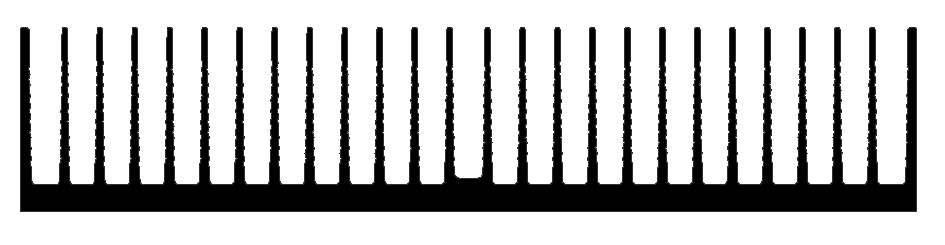

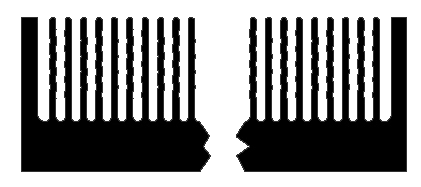

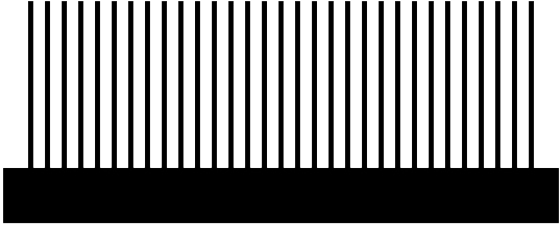

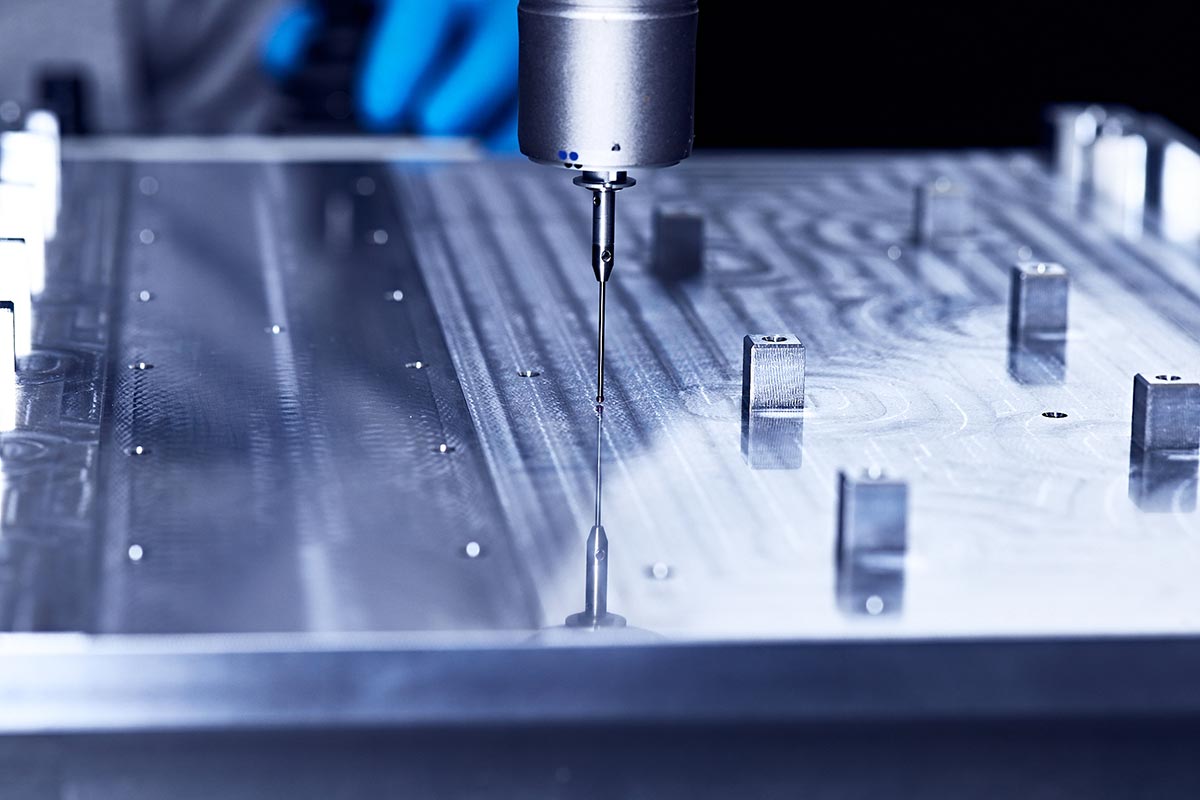

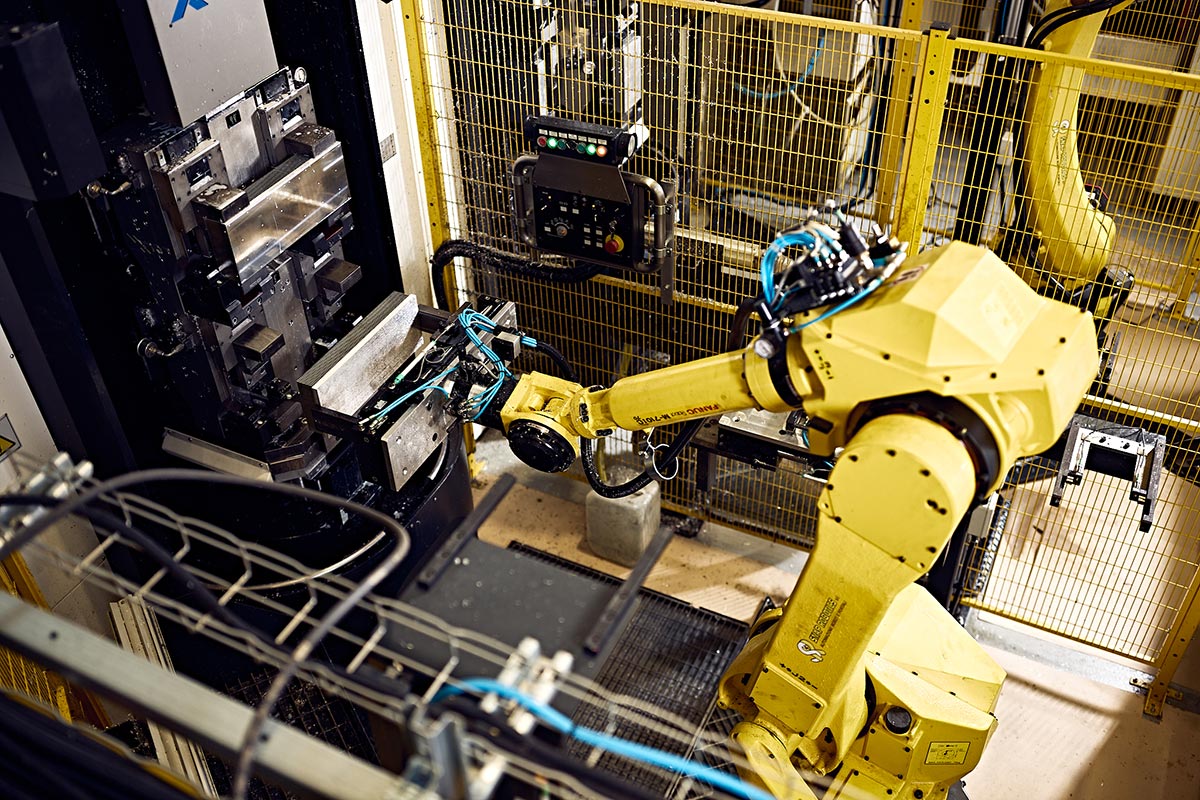

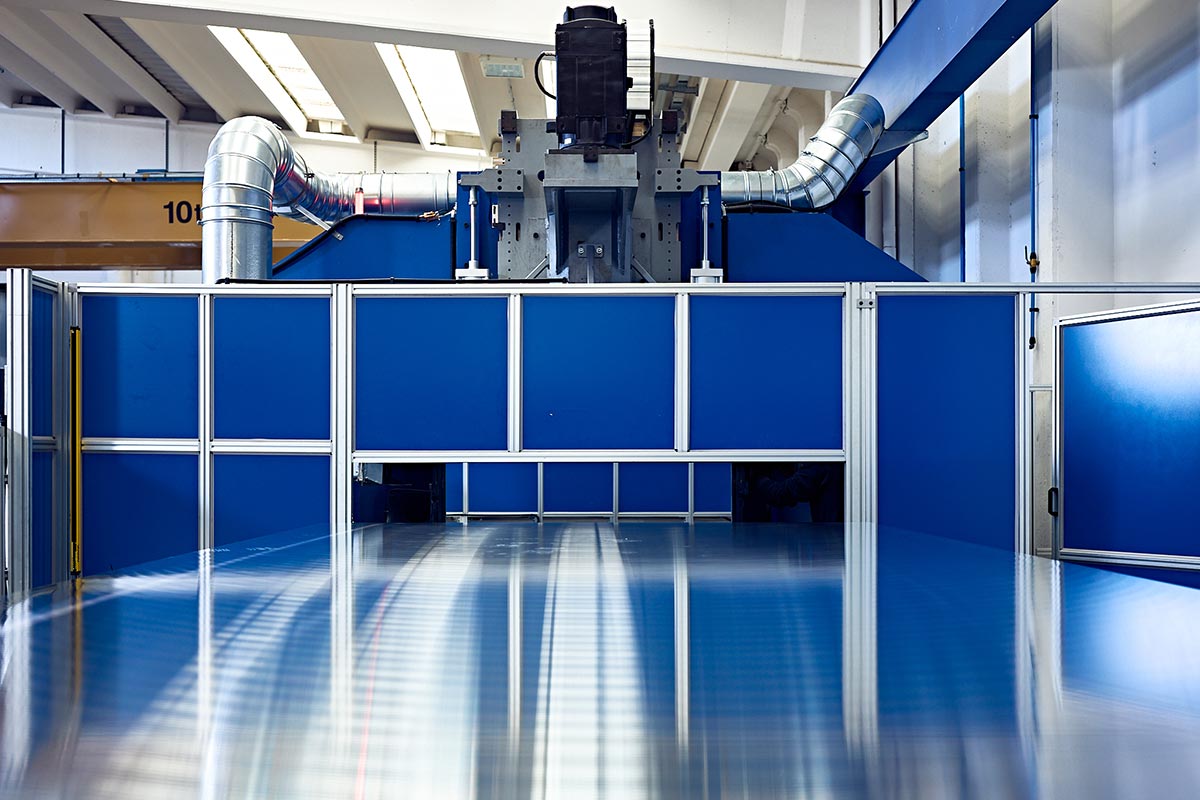

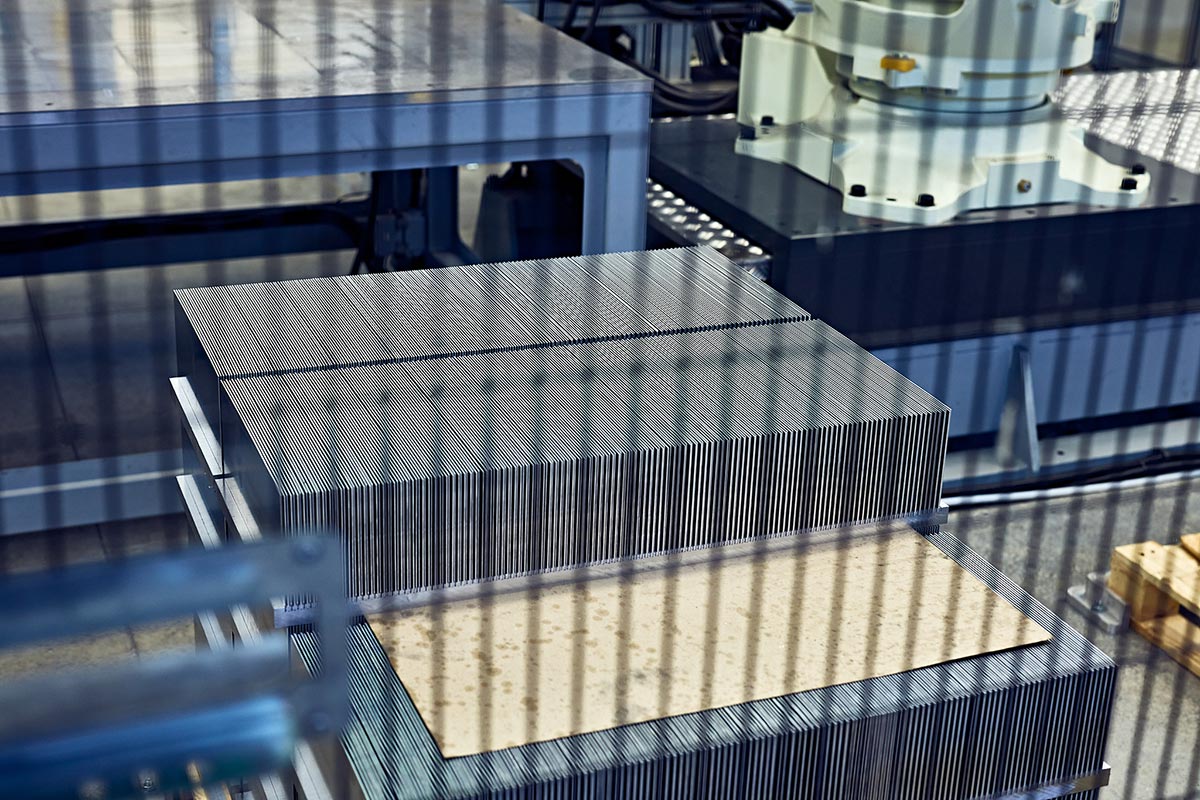

Mecc.Al manages the entire production cycle of its products internally—from profile creation to the finished product—thanks to direct control over every stage of aluminium production and a large warehouse stocked with extruded profiles, plates in various alloys, and coils of various thicknesses. The production process uses advanced technologies and latest-generation automated and robotised machining centres, ensuring high efficiency, precision and continuity of supply.

Production is guided by strict quality standards and international regulations for which the company is certified. The use of the latest CAD/CAM software and thermal simulation tools allows us to develop optimised solutions even for complex projects, ensuring total compliance with customer specifications from the earliest stages of development.

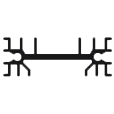

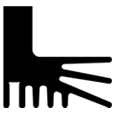

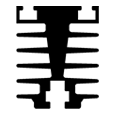

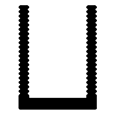

Aluminium is the main material used in our products due to its lightness, excellent thermal conductivity and remarkable workability. On request, we manufacture copper components and integrate accessory devices to further enhance the thermal performance of our thermal solutions.

- Raw material stock - plates, coils, extruded profile

- Automatic cutting and deburring machines

- High-power hydraulic presses

- TIG, MIG, FSW, induction welding and CAB brazing welding technologies

- Fully robotised multi-pallet CNC machines

- High-pressure deburring and washing systems, ultrasonic washing

- Surface treatments and gaskets

- CAD/CAM and thermal simulation software, automatic 3D measuring machines